BURL AND CROTCHES

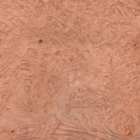

cluster di Maple

| Trade Names: | Maple Cluster |

| Similar Woods: | Madrona Burl, Plane Burl |

| Origin: | West Coast of the United States |

| Range: | One of the Maple family, Oregon Maple is known in the USA also as Big Leaf Maple. Occurrence is limited to the west coast strips of the USA and Canada with the most northern occurrence in Alaska and the southernmost border of the Sierre Nevada mountains as well as in San Diego County. Grows up to 1500 m altitude and is generally found in the company of other hard-woods such as Red Alder and softwoods like Douglas Fir or Western Red Cedar. The leaves are red veined. Apart from the burls, which develop directly over the root, Oregon Maple has no noteworthy significance as a commercial lumber. |

| Uses: | Highly decorative elements for filling or fronts in architectural woodwork and furniture production. |

| Properties: | Since Maple Burl frequently has bark pockets, sound large burls are seldom and very expensive. Almost always rotary cut. |

| Machining: | The extraordinary wood texture has to be taken into account when working. Perfect tools and slow machining speeds produce an attractive product. |

| Seasoning: | The burl texture calls for extremely careful drying to avoid higher losses through surface checking and warping.. |

| Finishing: | The surface has to be given a lustrous or polished finish |

| Jointing: | Good |

cluster di Maple

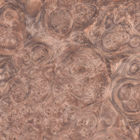

cluster di noce

| Trade Names: | Walnut Cluster |

| Similar Woods: | ----- |

| Origin: | Europe, Asia and North America. |

| Range: | Walnut cluster veneers are those veneers which are obtained from those bottom most parts of Walnut tree trunks, which partially grow underground. To obtain this valuable part of these trees the trunks must not be sawn above the ground but have to be dug out. The produced veneers have a particularly distinct, expressive figuring which gains a great deal of life from the many cross figures and mottling but still does not result in a burly texture. |

| Uses: | High quality architectural woodwork, as solid wood for gearshift knobs and high quality gunstocks. |

| Properties: | Dark brown choice wood, traditional furniture wood. Frequently with fiddleback. |

| Machining: | There is no difficulty to working with all hand and machine tools. Walnut is an excellent wood for molding. |

| Seasoning: | To prevent any possible damage to cells the wood should be dried very slowly. It is slightly prone to checking and warping. |

| Finishing: | The very smooth surface takes all stains well, particularly water and nitro stains. The wood polishes well when fillers are used. |

| Jointing: | Joints using screws, nails and glues are easy to produce and have normal tensile strength. However, alkaline glues can cause reaction stains. |

Walnut Cluster

cluster di olmo - ELM Cluster

| Trade Names: | Elm Burl |

| Similar Woods: | Oak Burl |

| Origin: | Central Europe |

| Range: | Mainly in France and England. Due to the Dutch Elm disease the occurrences are very rare. The majority of the felled burl trees are already dead, i.e. the heartwood is already stained dark brown. Sought are the still living trees, the heartwood of which is still showing the typical light brown, noble coloring. It can be assumed that in the near future it will no longer be possible to produce Elm Burl veneer. |

| Uses: | Very decorative veneer wood, high quality architectural wood-work and high class furniture making. In Central Europe mainly used as accentuating wood for decorative purposes; in Southern Europe due to fashion trends often also used for complete range of furniture. |

| Properties: | The color of the heartwood is light to dark brown. Fine-eyed burl veneer with large dimensions and few open defects or bark pockets are sold at very high prices. |

| Machining: | There is no difficulty to machining the slow grown grades with hand machine tools. Rough pieces are difficult to plane and shape. |

| Seasoning: | The burly texture calls for high care in drying to avoid degrading through surface checking and warping. The wavy texture also increases the demands put on machining to obtain a smooth surface without pick-up. |

| Finishing: | The wood takes any surface treatment well. Filler is recommended due to the coarse texture. High gloss surfaces are extremely impressive. |

| Jointing: | All wood joints with nails, screws and glue hold well although pre-drilling is to be recommended due to the tendency to split. |

Elm Burl

PIUMA DI CEREJEIRA – CEREJEIRA CROTCH

| Trade Names: | Cerejeira Crotch |

| Similar Woods: | Figured Oak |

| Origin: | South America |

| Range: | Limited to Argentine and Brazil , particularly in the Amazon basin. Logs as such are unknown in Europe, crotch wood is imported in small quantities, however. |

| Uses: | Architectural woodwork, more popular in the USA than in Europe. |

| Properties: | Difficult to slice . Some rough patches are almost impossible to avoid. |

| Machining: | Due to the interlocking grain machining calls for a slow feed speed. Planed surfaces are slightly rough and have to be sanded down. |

| Seasoning: | The tendency to check is particularly apparent with this species of wood and can only be reduced by careful drying. |

| Finishing: | It is easy to treat the surface of this wood with all finishes. For external use open pore varnishes are used, for the interior , varnishes and mat finishes are applied. |

| Jointing: | Glue joints hold firmly, screw and nail joints are very durable. |

Cerejeira Crotch

PIUMA DI MOGANO KHAYA – AFRICAN MAHOGANY CROTCH

| Trade Names: | African Mahogany Crotch, Khaya Crotch. |

| Similar Woods: | Tropical American Mahogany (South America) |

| Origin: | Africa |

| Range: | West Africa, Liberia, Ivory Coast , Ghana , Togo, Nigeria, Cameroon , Gabon, Congo, Zaire, Angola, lower tropical rain forests and tropical semi-evergreen rain forests. Principally differentiation is made between two species: Khaya ivorensis and Khaya antotheka. The difference, however, can only be seen with great difficulty if at all. Only Khaya ivorensis can be sliced. Khaya antotheka cannot be sliced due to the hardness of this wood. |

| Uses: | Mass-produced furniture ( traditional in England and USA ) , upright and grand pianos. In length of over 2 m for high quality architectural woodwork; such lengths are very seldom but are found more often in this species than is the case with American Mahogany Crotch. |

| Properties: | Differentiation must be made between the swirly part of the crotch and the actual crotch zone in which the full curl, the so-called “feather”, should be as straight as possible and show on the wood in one continuous line. Lengths over 2 m are extremely rare. |

| Machining: | In every way Khaya works well and easily. Only the partially interlocking grain should be taken into consideration, especially in the crotches. |

| Seasoning: | Natural seasoning and drying are easy and quick and present no particular difficulties. Slight warping can occur. |

| Finishing: | African Mahogany takes any surface treatment well and transparent or even luster varnishes are to be given preference for architectural woodwork. Glazes should be used for exterior work. |

| Jointing: | African Mahogany can be glued without any problem. Screw and nail joints should be pre-drilled. |

African Mahogany Crotch

PIUMA DI NOCE – WALNUT CROTCH

| Trade Names: | Walnut Crotch. |

| Similar Woods: | ----- |

| Origin: | North America (Juglans nigra) and very seldom in Europe (Juglans regio). |

| Range: | Branch forks of Walnut trunks. |

| Uses: | Architectural woodwork, upright and grand piano production, gunstocks. |

| Properties: | Lengths over 1 m very seldom, often open in the crotch. |

| Machining: | The wood is easy to work with all hand and machine tools. Walnut is excellent to mold. The direction of growth must be observed to prevent fibre pick-up. |

| Seasoning: | Drying has to be carried our with particular care where the Walnut crotch is concerned so that no tension checking occurs in the crotch part. |

| Finishing: | The very smooth wood takes all stains well particularly water and nitro stains. The wood polishes well when fillers are used. |

| Jointing: | Joints using screws, nails and glue are easy to produce and are of normal tensile strength. However, alkaline glues can cause reaction stains. |

Walnut Crotch.

RADICA DI AMBOINA – AMBOYNA BURL

| Trade Names: | Amboyna Burl, Narra. |

| Similar Woods: | ----- |

| Origin: | Indonesia ; the burl form especially on the Andaman group of Islands. |

| Range: | Amboyna burl is one of the rerest and most expensive woods in the world. The burly part of the log is often very small ( 20-30 kg) this only veneer in small dimensions. |

| Uses: | Highest quality architectural woodwork. Amboyna burl was a popular and frequently used wood in the Jugendstil epoch in the twenties. It was also the first burl wood to be used by Rolls Royce for dashboards. |

| Properties: | Very sound burl veneer which is only available in small dimensions. Coloring is from deep yellow orange to deep red. After surface finishing Amboyna burl reveals a depth and liveliness in colour like found in no other burl. |

| Machining: | The interlocking grain causes considerable problems, particularly when being planed to produce a smooth surface. The different density and hardness zones can only be machined with the greatest of care, appropriate to the value of this wood, to achieve an expert degree of perfection. |

| Seasoning: | Here again , drying sould be carried our very slowly and carefully to avoid surface checking and inner tension. Rough pre-cutting of the burly part considerably improves its drying behaviour. |

| Finishing: | Amboyna burl takes any type of surface treatment and is excellently suited for polishing. Ultraviolet-resistant varnishes should be used to avoid darkening in time. |

| Jointing: | Joints using glue and screws are easy to produce and hold very firmly. |

Amboyna Burl

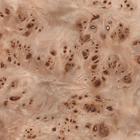

RADICA DI BETULLA - BIRCH BURL

| Trade Names: | European Birch, Norway Burl, Karelian Burl, Karelian Birch, Alpine Burl |

| Similar Woods: | ----- |

| Origin: | North Europe |

| Range: | Birch Burl logs are primarily found in Central to East Finland and also in Russia (Karelia) in the extensive Birch forest stands there. However, it is always a case of just odd trees which have developed this special form of growth. It is either genetic or caused by the soil conditions and the locations. There are strict felling quotas in Finland which are stringently controlled. As a general rule the usable length fon veneers is from 50 cm to 15 cm. To be considered as absolutely rare are usable logs of 200 cm 300 cm. in length. Due to their small diameter Birch burl logs are rotary cut. This is why the width of the veneer sheets is generally greater than their length. One log rarely yields more them 3-4 bundles. |

| Uses: | High quality architectural woodwork. |

| Properties: | The burl form is not the usual kind of burl development but generally shows a firmly ingrown pattern of many small, black deposits (eyes). These are spread more or less regularly over the surface of the veneer thus producing the attractive pattern. |

| Machining: | The wood can be worked well and easily with all tools. Planed surfaces are very smooth. |

| Seasoning: | Birch Burl calls for very slow and careful drying to keep tension checking and warping at the lowest possible level. Perfect tools prevent fibre pick-up on the surfaces. |

| Finishing: | Surface treatment causes no difficulties. |

| Jointing: | Glue is taken well by Birch Burl and joints hold well. Screw and nail joints should be pre-drilled. |

BIRCH BURL

RADICA DI CASTAGNO - CHESTNUT BURL

| Trade Names: | Chestnut Burl. |

| Similar Woods: | Oak Burl. |

| Origin: | Europe, Asia. |

| Range: | Occurs very seldom as burl or cluster, but if so mostly in Southern Europe. |

| Uses: | Architectural woodwork, not suitable for mass-produced furniture because of the scarcity of this wood. |

| Properties: | Very decorative. |

| Machining: | The machining of dried lumber presents no special problems. It can be easily planed, molded and turned. |

| Seasoning: | The somewhat difficult drying is made even more problematic by the burly texture of the wood. Draft and heat must be avoided by all means. Drying free of checking and tension can only be achieved by taking the greatest care. |

| Finishing: | Machining should be carried out at low feed speeds to prevent fibre pick-up in the surface. |

| Jointing: | Gluing of Chestnut burl is possible without difficulty. Screw and nail joints hold firmly. Due to the high tannin content reaction stains can occur when coming into contact with metal. |

Chestnut Burl

radica di eucalipto

| Trade Names: | Eucalyptus Burl |

| Similar Woods: | Elm Burl |

| Origin: | Australia, New Zealand and also in Spain today. |

| Range: | Due to current plantation cultivation of Eucalyptus in North-Western Spain and Portugal , Eucalyptus veneers are being produced for the domestic market there. Burl growth in Eucalyptus is very seldom, also in Australia and New Zealand. That is why this wood cannot be used for mass production but only for architectural woodwork. |

| Uses: | High quality architectural woodwork. |

| Properties: | The varieties extend from the pommele type to the distinct burl. Unlike other burl woods this does not occur through fine branch growth but is a pure growth characteristic of this tree, getting its burly appearance from the wavy course of the grain. |

| Machining: | Due to the very dense and wavy grain it is not easy to machine. The wood splits very easily at the edges and when planing fibre pick-up occurs on the surface. |

| Seasoning: | Drying is very difficult and extremely slow. When drying wood shrinkage is very high which leads to inner tension and surface checking. There is a strong tendency for the wood to warp. |

| Finishing: | Clear varnishes or polished surfaces are suitable to highlight the burly texture . These finishes are applied in the normal way. |

| Jointing: | Joints with glue, screws and nails are easy to produce and hold firmly. |

Eucalyptus Burl

RADICA DI FRASSINO BIANCO - WHITE AHS BURL

| Trade Names: | European Ash, White Ash Burl |

| Similar Woods: | Myrtle Burl |

| Origin: | Europe, but generally restricted to Western Europe |

| Range: | The Ash Burl is a trunk burl, i.e. the burl forms in the trunk and not in the root. Generally it is a matter of freestanding or small groups of trees on which a lot more branches have developed due to external influences. This, together with the ever changing direction in growth and continuous over-growing, results in the final burl. |

| Uses: | High quality architectural woodwork as well as high quality produced furniture, widely used in the USA and the Far East. |

| Properties: | Completely sound, large dimensioned, full burl logs are very rare. Frequently either small black knots are found in the burl or more of a cluster type, i.e. the burl zones are spread over the surface and are linked with each other through wild textures. |

| Machining: | Ash can be worked easily and well with all tools. Coarse grown logs tend to split at their planed edges. Very smooth surfaces are produced. |

| Seasoning: | The drying operation should be carried out at moderate temperatures and not too hurriedly. There is only a slight tendency to warp. Surface checking very seldomly occurs . |

| Finishing: | Ash is suitable for all kinds of surface treatments and colored stains are in particular. Their use presents no problems. |

| Jointing: | Glue is taken well by Ash and produces very durable joints. Pre-drilled screw joints hold well. |

White Ash Burl

RADICA DI FRASSINO OLIVATO - OLIVE AHS BURL

| Trade Names: | Olive Ash Burl |

| Similar Woods: | ----- |

| Origin: | Europe, but generally restricted to Western Europe |

| Range: | These are Ash Burl trunks with colored heart. Since the colored heart develops irregularly, due to the wild texture of the wood, the veneer pattern frequently has interesting light and dark compositions. |

| Uses: | High quality architectural woodwork, used also in Southern Europe for furniture. |

| Properties: | Extremely decorative through the alternating light and dark coloring. Can be made available in veneer having large dimension. |

| Machining: | Problems can occur in the form of fibre pick-up from the surface due to the burl growth. |

| Seasoning: | As is the case with all burls, drying is to be carried out slowly and carefully. When drying too quickly the different directions of shrinkage are so great that the given tension can cause checking, both on the surface and inside the wood, which can lead to total degrading. |

| Finishing: | Ash is suitable for all kinds of surface treatments. Colored stains are used in particular. Their application presents no difficulties. |

| Jointing: | Glue is readily accepted by Ash and produces very durable joints. Pre-drilled screw joints hold well. |

Olive Ash Burl

RADICA DI IMBUIA – IMBUYA BURL

| Trade Names: | Imbuya, Imbuya burl. |

| Similar Woods: | ----- |

| Origin: | South America. |

| Range: | South America , especially South Brazil: Parana and St. Catarina; moist soils of tropical mountainous rain forest growing at lower altitudes. |

| Uses: | Very rare veneer wood exclusively used for choice architectural work. Especially popular as accentuating wood for fillings in combination with other high quality ones. |

| Properties: | The heartwood is brown in yellow , olive to chocolate shades. The wood is durable and resistant to insect attack, moderately hard, of medium weight and elastic. Apart from Imbuya Burl this wood has had very little significance in Europe up to now. The Burl is only used in Europe for high quality architectural woodwork because of its rareness. |

| Machining: | To produce smooth, non-checked surfaces Imbuya Burl must be very carefully worked due to its burl formation. When cleanly machined the surfaces have a beautiful luster which can also facilitate further treatment. |

| Seasoning: | The wood must be dried very slowly and extremely carefully because Imbuya is strongly prone to warping. There is no strong tendency to checking. |

| Finishing: | Surface treatment of any type is very easy to carry out and polished surfaces in particular highlight the burly texture. |

| Jointing: | Glue joints are easy to produce and hold firmly. Pre-drilled screw and nail joints have high tensile strength. |

Imbuya burl.

radica di madrona - MADRONA BURL

| Trade Names: | Madrona Burl |

| Similar Woods: | Maple Burl, Plane Burl |

| Origin: | USA. |

| Range: | In North America down the Pacific Coast from Canada to California and Mexico. The Madrona Burl produces its burl growth as root growth half over and half under the soil, i.e. the burls must be dug out to obtain them. In the Usa this is done by hand in many cases to prevent damage to the valuable wood by heavy machinery. |

| Uses: | Rotary cut wood for choice face veneers, luxury architectural woodwork, luxury furniture, inlays and cabinet making. |

| Properties: | The wood is reddish-brown and the root burls are very dense with generally closed grain. The tree grows very slowly and, depending upon actual location, is straight without any branches but can also be bent or occur in bush form. The wood is weather resistant, very hard and tough. Root burls are purchased by weight. |

| Machining: | Due to irregular grain considerable more power is required for machining. Smooth surfaces are difficult to produce. This problem is overcome to a certain extent by steaming before slicing. |

| Seasoning: | Madrona burl must be dried very slowly and carefully to take into account the problem of different shrinkage directions resulting from the wavy grain. |

| Finishing: | Surface treatment with all finishes is possible but calls for through pretreatment to obtain a smooth surface. |

| Jointing: | Joints with Madrona Burl are restricted to glues and screws but those can be produced without any problems. |

Madrona Burl

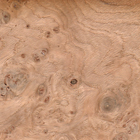

RADICA DI MAPLES - MAPLE BURL

| Trade Names: | Maple Burl |

| Similar Woods: | Madrona Burl, Plane Burl |

| Origin: | West Coast of the United States |

| Range: | One of the Maple family, Oregon Maple is known in the USA also as Big Leaf Maple. Occurrence is limited to the west coast strips of the USA and Canada with the most northern occurrence in Alaska and the southernmost border of the Sierre Nevada mountains as well as in San Diego County. Grows up to 1500 m altitude and is generally found in the company of other hard-woods such as Red Alder and softwoods like Douglas Fir or Western Red Cedar. The leaves are red veined. Apart from the burls, which develop directly over the root, Oregon Maple has no noteworthy significance as a commercial lumber. |

| Uses: | Highly decorative elements for filling or fronts in architectural woodwork and furniture production. |

| Properties: | Since Maple Burl frequently has bark pockets, sound large burls are seldom and very expensive. Almost always rotary cut. |

| Machining: | The extraordinary wood texture has to be taken into account when working. Perfect tools and slow machining speeds produce an attractive product. |

| Seasoning: | The burl texture calls for extremely careful drying to avoid higher losses through surface checking and warping. |

| Finishing: | The surface has to be given a lustrous or polished finish. |

| Jointing: | Good |

Maple Burl

RADICA DI MIRTO - MYRTLE BURL

| Trade Names: | Myrtle Burl, Pepperwood, Laurel |

| Similar Woods: | White ash Burl |

| Origin: | North America |

| Range: | On the Pacific Coast of the USA, from Oregon in the north to Southern California. Myrtle is a species of the Laurel tree. The burl is a root burl which forms in the stump. The tree itself has no commercial significance. It is rather bushy in growth and is often found in woods growing in the valleys of hilly country. |

| Uses: | High quality architectural woodwork, also used for furniture. |

| Properties: | Since the Myrtle develops a dark heart, differentiation has to be made between those veneers without heart, which are yellowish in colour, and those having a dark brown heart. This is why Myrtle Burl is also frequently stained to enable both forms to be used. The aromatic odour of the wood is most apparent. |

| Machining: | Despite the burly texture it is very easy to work and smooth surfaces are produced by all methods. |

| Seasoning: | As is the case with all burls, drying must be carried out very carefully but Myrtle is not highly prone to checking and warping. |

| Finishing: | Due to the burly texture and very smooth surfaces Myrtle is excellently suited for polishing. The use of a walnut colored stain is recommended to compensate differences in color within the burl. |

| Jointing: | Glue joints hold well. Screw joints hold firmly but should be pre-drilled. |

Myrtle Burl

radica di noce

| Trade Names: | Walnut burl, Californian Walnut burl |

| Similar Woods: | ----- |

| Origin: | West coast of the USA fro Southern California to Oregon. |

| Range: | The burl is only a “by-product”, the actual purpose of the tree is to grow nuts. To this and gigantic walnut plantations have been set up where the American Walnut (juglans regia) is being grafted to the European Walnut (juglans nigra). As a result root burl growth develops below the grafting point. After the productive capacity of the trees for nuts has been exhausted these burls are dug up as a second product and sold. |

| Uses: | Highest quality interior work and furniture production. Used in larger quantities for dashboards by the automobile industry. Also used for high quality instruments in the production of upright and grand pianos. Most desirable as solid wood for gearshift knobs. |

| Properties: | Walnut burl occurs in many different forms. From head veneer and cluster to solid burl which now as before numbers amongst the most expensive and most sougth after veneers. Splitting often occurs within the trunk. |

| Machining: | The wood is easy to work with all hand and machine tools. |

| Seasoning: | The burl texture calls for extremely slow and careful drying to keep tension in the wood as low as possible. Mechanical machining also requires the greatest of care to prevent surface fibre pick-up. The texture of the burl is highlighted best by high gloss varnishes and polishing. |

| Finishing: | The very smooth surface takes all stains well, particularly water and nitro stains. The wood polishes well when fillers are used. |

| Jointing: | Joints using screws, nails and glues are easy to produce and have normal tensile strength. |

Walnut burl

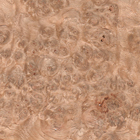

RADICA DI OLMO - ELM BURL

| Trade Names: | Elm Burl |

| Similar Woods: | Oak Burl |

| Origin: | Central Europe |

| Range: | Mainly in France and England. Due to the Dutch Elm disease the occurrences are very rare. The majority of the felled burl trees are already dead, i.e. the heartwood is already stained dark brown. Sought are the still living trees, the heartwood of which is still showing the typical light brown, noble coloring. It can be assumed that in the near future it will no longer be possible to produce Elm Burl veneer. |

| Uses: | Very decorative veneer wood, high quality architectural wood-work and high class furniture making. In Central Europe mainly used as accentuating wood for decorative purposes; in Southern Europe due to fashion trends often also used for complete range of furniture. |

| Properties: | The color of the heartwood is light to dark brown. Fine-eyed burl veneer with large dimensions and few open defects or bark pockets are sold at very high prices. |

| Machining: | There is no difficulty to machining the slow grown grades with hand machine tools. Rough pieces are difficult to plane and shape. |

| Seasoning: | The burly texture calls for high care in drying to avoid degrading through surface checking and warping. The wavy texture also increases the demands put on machining to obtain a smooth surface without pick-up. |

| Finishing: | The wood takes any surface treatment well. Filler is recommended due to the coarse texture. High gloss surfaces are extremely impressive. |

| Jointing: | All wood joints with nails, screws and glue hold well although pre-drilling is to be recommended due to the tendency to split. |

Elm Burl

RADICA DI PIOPPO - MAPA BURL

| Trade Names: | Mapa Burl, Mapi Burl |

| Similar Woods: | ----- |

| Origin: | Central and Western Europe |

| Range: | Mapa Burl are Poplar trees which develop abnormal trunk formations as a result of external influences, i.e. burl growth in the form of widely scattered, little spots n their trunks but not in their roots giving the veneer its burly appearance. The occurrence of Mapa Burl logs suitable for veneer extends from the meadowland along the German Rhine River across to Northern and Southern France. |

| Uses: | As rotary cut wood for high quality face veneer. The wood is not steamed, i.e. rotary cut cold. |

| Properties: | The heartwood is light brown to brown. The burl occurs as reddish clack spots. The veneer in which these dots are spread as evenly as possible over the surface is highly desired. The Populus nigra is the only species of Poplar which develops these burls. |

| Machining: | The wood is easy to work with all mechanical tools. However, because of the burly growth very sharp tools are needed to prevent a rough surface. Slow feed speeds are to be recommended. |

| Seasoning: | Even when dried very slowly and carefully it is not possible to fully prevent surface checking due to the different directions of shrinkage. |

| Finishing: | |

| Jointing: |

Mapa Burl

RADICA DI ROVERE - OAK BURL

| Trade Names: | Oak Burl |

| Similar Woods: | Elm Burl |

| Origin: | Entire Europe. |

| Range: | The burl growth of the Oak is to be found mostly in the western and south western regions of Europe (no knowledge of Oak Burl in Eastern Europe to date). Oak Burl generally develops in trunks with colored heart. Since the colored heart develops in isolated Oaks having sufficient space for this growth. |

| Uses: | High quality interior architectural work. Unlike the more frequent Knotty Oak which is also used for mass production furniture. |

| Properties: | Main quality criteria for Oak Burl is the ingrown bark which is found almost on every tree. The quality of the veneer is all the better the less ingrown bark there is because it is less expensive to process then. Logs without ingrown bark are extremely rare. |

| Machining: | Despite its hardness Oak can be worked well with all tools. Planed surfaces are very smooth. Good results can be achieved when molding and turning. |

| Seasoning: | Drying of Oak is an extremely slow process. There is a strong tendency for Oak towards surface checking and inner case-hardening. Only the greatest if care con ensure satisfactory drying. |

| Finishing: | The surface treatment of Oak with all finishes is good and causes non problems. The use of stains should be restricted to the American Oak. |

| Jointing: | Glue joints are strong and durable. Screw and nail joints hold firmly but can cause discoloration in the wood through the effects of moisture. |

Oak Burl

radica di Thuya

| Trade Names: | Thuya Burl |

| Similar Woods: | Vavona Burl |

| Origin: | North Africa |

| Range: | Algeria , Tunisia, Marocco , odd trees on the island of Malta and in Southern Spain. The Thuya Burl is a figured root burl, with only very small dimensions in the majority of cases. We speak of the Softwood Cedar here. |

| Uses: | Since only small dimensions are possible the Thuya Burl is used as filler for highest quality furniture. It is also popular for cigar boxes, cases for spectacles and alike, occasional furniture and cabinet making. |

| Properties: | Generally it is finely textured with interlocked grain. The wood is quite prone to show inner cracks so that very careful splicing is necessary. Moreover, Thuya burl gives off an intensive, very aromatic and pleasant odour. |

| Machining: | Working this very hard wood calls for the greatest of care to prevent checking in the surface as a result of its burl growth. However , very smooth and slightly lustrous surfaces can be achieved when properly machined. |

| Seasoning: | Since the wood neither tends to check or warp it can be dried without any great difficulties. In some cases the burl veneers are only air dried to ensure a higher moisture content to make machining easier. |

| Finishing: | To highlight the decorative veneer pattern preference is to be given to lustrous or polished finishes. These can be produced without any particular problems. |

| Jointing: | Glued joints can be produced without any difficulty and hold firmly. The same applies to screw joints. |

Vavona Burl

radica di vavona

| Trade Names: | Vavona Burl |

| Similar Woods: | Thuya Burl |

| Origin: | North America |

| Range: | The coastal region of Northern California and Southern Oregon. Seldom occurs more than 30 miles away from the Pacific or at altitudes over 3,000 feet. The burl is the root of the Mammoth tree and is often gigantic in size. The burls have to be dug out which often involves a great deal of work. |

| Uses: | High quality architectural woodwork, furniture production possible but only produced in Southern Europe so far. |

| Properties: | The Vavona burl is deep dark red in colour and in principle one can differentiate between two types: 1) Lace form: the actually burly wood. 2) Birdseye form : fine, darkly pronounced dots are scattered over the surface similar to the Birdseye Maple. The veneers are relatively fragile. |

| Machining: | Vavona can only be worked with very sharp tools with the greatest of care and due consideration to the burl formation. However, produced surfaces are satisfactory. |

| Seasoning: | The wood must be dried extremely slowly to avoid checking in the burl surface. The more carefully the wood is dried the better the result. |

| Finishing: | A polished surface is recommended to highlight the burly texture but a light gloss should be produced at least. |

| Jointing: | Gluing of Vavona, mainly as veneer, can be carried our satisfactorily. Screw joints must be pre-drilled. |

Vavona Burl

ROVERE CON NODI - KNOTTY OAK

| Trade Names: | Knotty Oak |

| Similar Woods: | ----- |

| Origin: | Europe |

| Range: | The most frequent species of tree in the European forest mostly occurs as pedunculate or sessile oak. The most well known locations for high quality veneer oak are Spessart and Palatine in Germany and Trocais in France. Oak does not exist in Middle and North Scandinavia or in West, Central and South Spain. Very good dimensions over 0.80 m are nothing unusual. The Knotty Oak develops a great many epicormical branches. |

| Uses: | Sliced wood for decorative veneer. |

| Properties: | Used are Oaks which have developed many pin knots, however, those should be sound and closed. Knotty Oak veneers are used to little extent in the production of mass-produced furniture but mostly employed for interior work. See: European Oak. |

| Machining: | Despite its hardness Oak can be well machined with all tools. Planed surfaces are very smooth. Good results can be achieved when molding and turning. |

| Seasoning: | The risk of producing degraded wood is increased through checking in the knot zones when drying. Fibre pick-up can also occur in these zones when machining. |

| Finishing: | Oak can be finished well and without difficulty with all surface treatments. Use of stain is to be restricted to American Oak. |

| Jointing: | Glue joints are durable, screw and nail joints hold firmly mbut can cause discoloration in the wood under the influence of moisture. |

Knotty Oak